Hydropuls Testing for Components

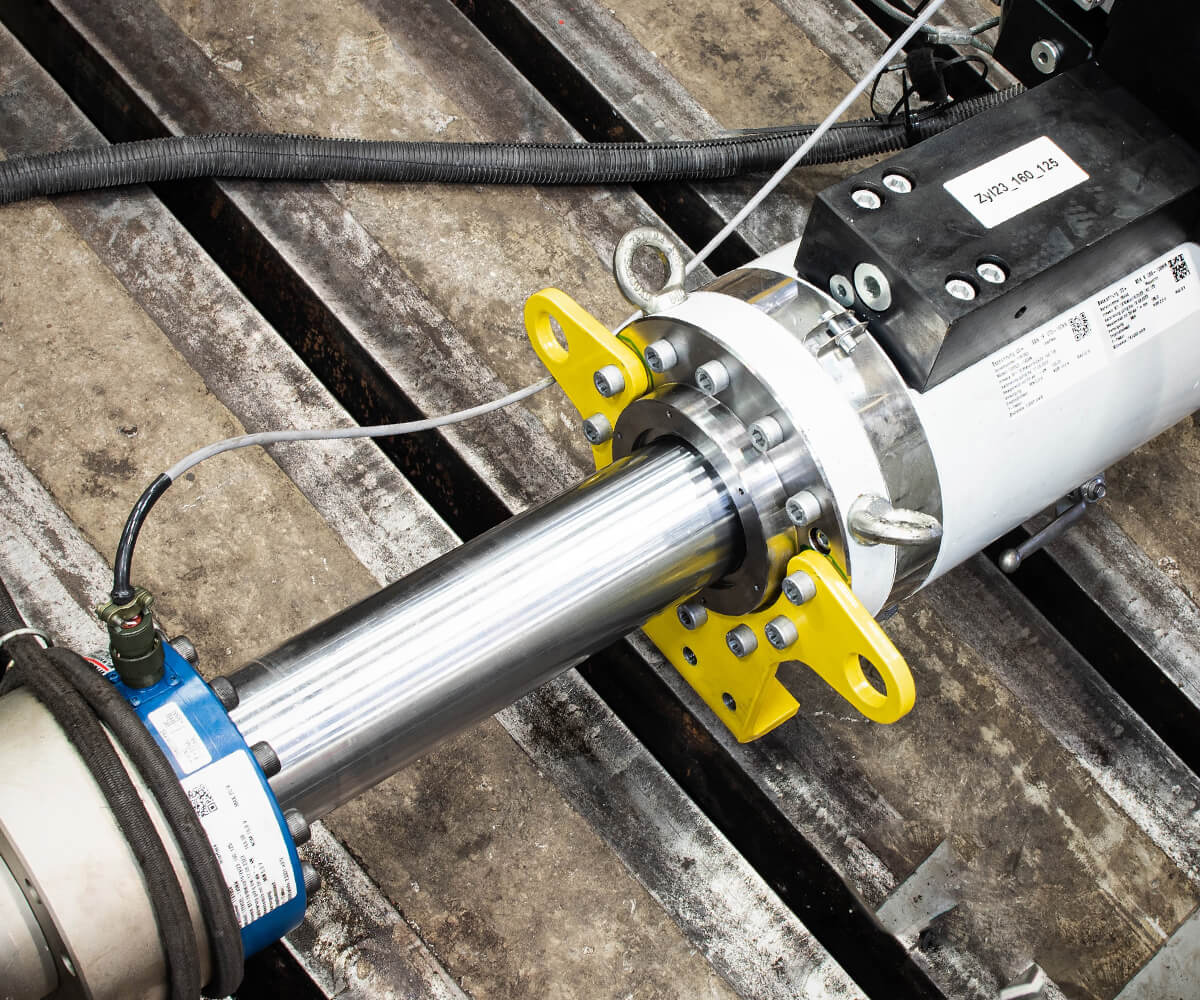

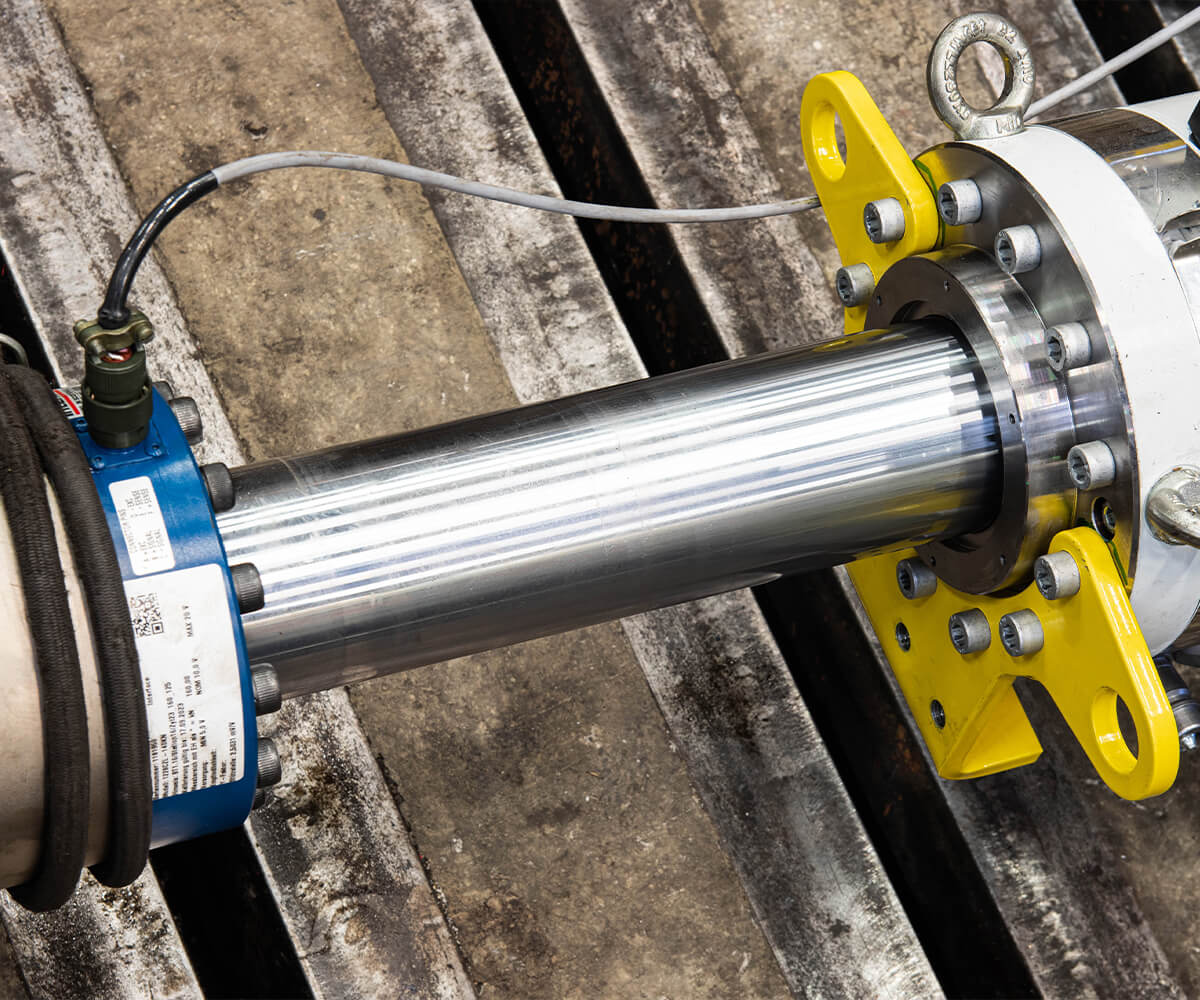

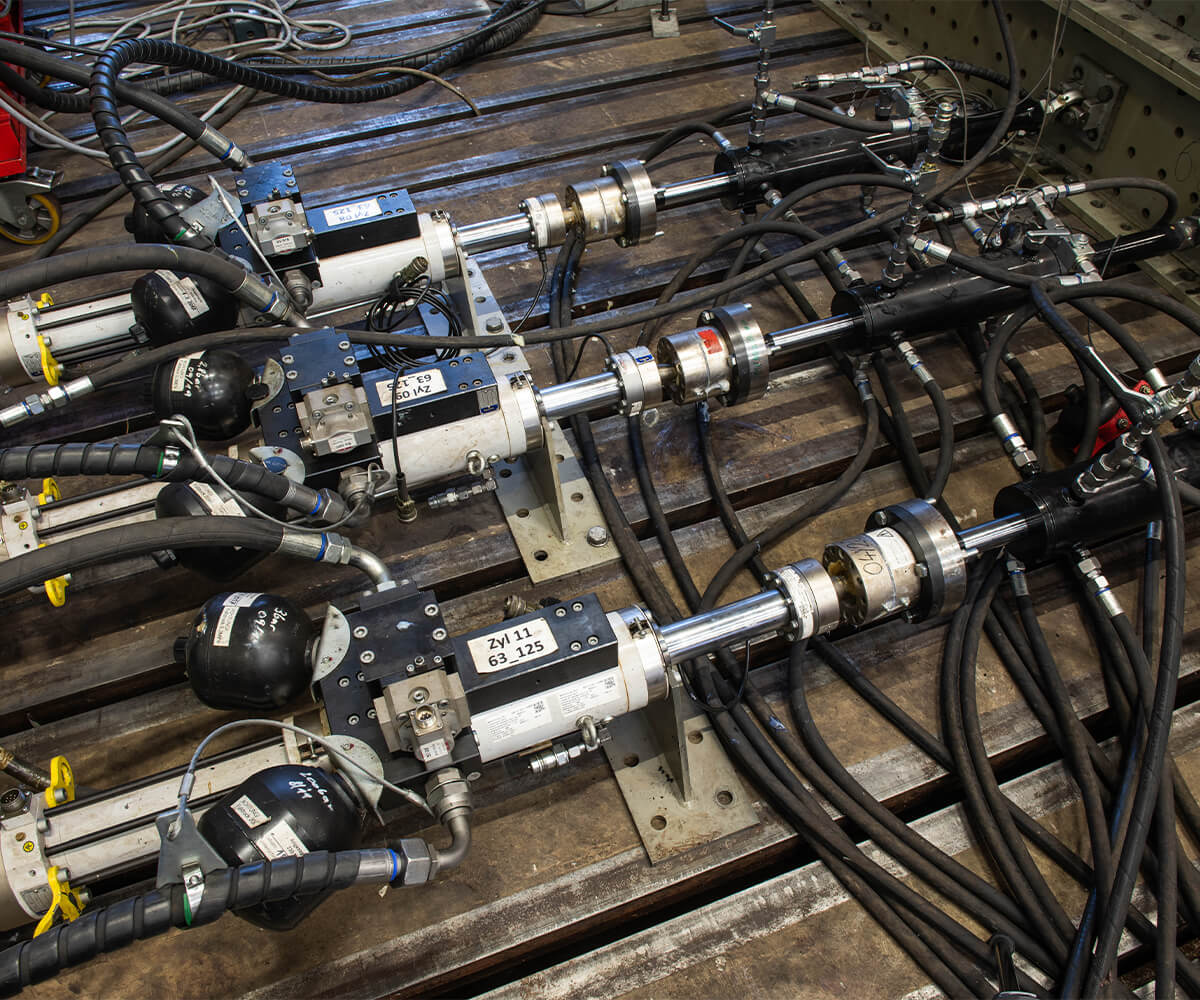

The Hydropuls Testing field offers because of its modular design the ability to create rapid test constructions.

By servo-hydraulic Hydropuls cylinders, precisely forces and movements are applied to the component. With a size up to 22 x 12 meters tests on components of nearly all sizes can be made – from smaller superstructures for agricultural equipment to transport superstructures to large components for the aerospace industry.

Hydropuls Testing

for Components

The Hydropuls Testing field offers because of its modular design the ability to create rapid test constructions.

By servo-hydraulic Hydropuls cylinders, precisely forces and movements are applied to the component. With a size up to 22 x 12 meters tests on components of nearly all sizes can be made – from smaller superstructures for agricultural equipment to transport superstructures to large components for the aerospace industry.

Possible applications

- Endurance testing of components under vibration loads

- Functional testing of machines under vibration and external loads

- Static load tests

- Durability, fatigue & transport studies